Tecnology

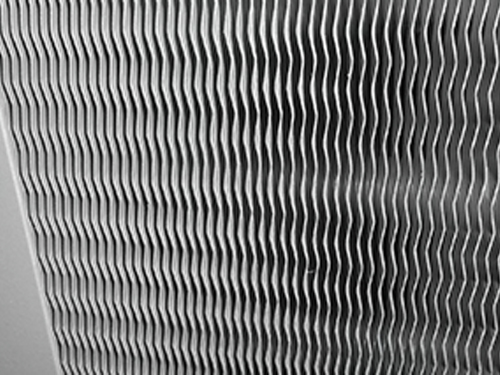

Let us start with a definition of a finned pack heat exchanger commonly called a coil. In its basic version it is formed by a round copper tube and an aluminium fin.

The coil is an important component of units like water chillers, aircooled condensers,dry coolers and from its performance depends most of the energy consumption of a cooling system.

In the coils the primary fluid running in the tubes can be: water , refrigerant or steam while the secondary fluid going through the fins is invariably air.

Let us now give a definition of corrosion: it is a process which leads to the alteration or destruction of a metal.

Metals are notoriously subject to corrosion and particularly from athmospheric agents. The two most common forms of corrosion are known as:

- galvanic corrosion

- corrosion from athmospheric impact

Galvanic corrosion

Corrosion from athmospheric impact

We call in this way the corrosion created by a reaction with the environment.

We call in this way the corrosion created by a reaction with the environment.As said before the secondary fluid of a coil is always air.

Unfortunately air is almost never pure and uncontaminate. In fact, very often, air contains elements which are highly corrosive for copper and aluminium.

Some examples of environments with polluted air:

- Industrial ambients/li>

- Urban ambients

- Rural ambients

- Marine ambients

1 | Industrial ambients

The industrial areas are almost always associated with emission in the athmosphere of various pollutants like sulphur and nitrogen oxides.The combustion of solid fuels releases sulphur oxides (SO2, SO3) and nitrogen oxides (NOx). These gases accumulate in the athmosphere and return to the ground as acid rains or low pH dews (acid dews). In an industrial athmosphere there are normally also particles of metallic oxides, chlorides, sulphates, sulphuric acid, carbon and carbon compounds. These particles in the presence of oxygen, water or high humidity can be extremely corrosive.2 | Urban ambients

Densely populated areas are always associated with emissions in the athmosphere of car discharge gases and, during the heating periods, of high contents of combustion products. Both conditions increase the concentration of sulphur and nitrogen oxides.3 | Rural ambients

The rural ambients can contain high levels of ammonia deriving from fertilizer and animal drop-outs.4 | Marine ambients

Coastal areas in the proximity of the sea are characterized by an abundance of sodium chloride (salt) which is transported by spray, fogs and mist. The saline athmosphere induces per se corrosion but, most of all, acts as a catalyzer of corrosion in the presence of industrial emissions. A marine-industrial environment is probably the worst situation from the corrosion point of view.Main effects of coil corrosion: loss of efficiency and increase of energy consumption

A coil is fundamentally a heat exchanger and heat is transferred through the tube surface to the fin. The fin is in close contact with the tube which is, in fact, expanded into the fin collar.The first effect of pollution on the fin is a deposit of dirt on it, partially isolating the secondary heat exchange surface from contact with the air. Further on, when the dirt particles have been in contact for a sufficiently long time and the corrosion process is started (corrosion from athmospheric impact), the finned surface starts to deteriorate, decreasing the heat exchange capacity.One should not forget that the fin thickness is of the order of magnitude of 0.17 mm. and the corrosion does not take too long a time to eat up such a low thickness.

In the same time the galvanic corrosion, that appears at the bimetallic contact between copper and aluminium, erodes the collar eliminating the close contact between tube and fin. Decreasing the heat exchange even more.

The disappearance of the collar exposes the tube; some crystals can be deposited and this can lead to a pitting corrosion which provokes a leak of the primary fluid. If this is refrigerant, as it is for all condensing coils, it will cause the stop of the unit, adding in the same time, additional pollution to the athmosphere.

Corrosion protection

The most common method of corrosion prevention is to coat the parts exposed to corrosion, avoiding the contact with the polluting agents. This method can be applied also to coils, however we must keep in mind some important points:

- the coils are heat exchangers. A coating acting as an insulating layer is not appropriate;

- the fins have a special configuration which increases the air turbulence thus improving the heat exchange. The coating must not modify the fin configuration;

- the application of a layer of coat on both fin sides reduces the air passage area. This generates a higher pressure drop which either reduces the air flow or increases the absorbed power.

The above points have a vital importance and must be kept in mind when selecting the proper protection. There are however other protection features which are convenient:

1 - good flexibility of the protection layer to follow the metal thermal expansion/contraction;

2 - dirt repellence: the air passing through the fins deposits dirt which will adhere less easily if the coating is particularly smooth;

3 - U.V. resistance quite important for coils exposed to the sun;

4 - maintenance: the protection, however good its quality, will have a resistance to athmospheric agents limited in time. It is advisable to re-apply the product as soon as signs of deterioration appear. As we shall see some coating methods do not allow re-applying the products;

5 - reduced cost of application: much as the method of application can be technically advantageous it must be economically significant.

The traditional solutions do not offer the guarantees that Post-Coating can feature

In the market we have seen in the past several solutions to protect from corrosion but almost all had weak points in one or another direction. Use of different metals : a possible solution is to employ a coil with copper tubes and copper fins. This surely eliminates the galvanic corrosion. But copper is attacked by sulphur gases which are often present in industrial ambients and not only there. The cost of the copper fin is, in any case, quite high. An even more costly solution is the tinning of the copper fin. If made by dipping the cost is really prohibitive. If obtained by using a pre-tinned coil it will have no effectiveness as the cuts deriving from the fin press moulding will uncover the underlying metal which is no longer protected.

Use of different metals : a possible solution is to employ a coil with copper tubes and copper fins. This surely eliminates the galvanic corrosion. But copper is attacked by sulphur gases which are often present in industrial ambients and not only there. The cost of the copper fin is, in any case, quite high. An even more costly solution is the tinning of the copper fin. If made by dipping the cost is really prohibitive. If obtained by using a pre-tinned coil it will have no effectiveness as the cuts deriving from the fin press moulding will uncover the underlying metal which is no longer protected.

Surface coating: the basic idea is to eliminate totally the contact between the polluted air and the metal. We can distinguish two methods of application of the coating:

- Pre-coating

- Post-coating

Pre-coating: it is a layer of coat of few micron thickness applied on the aluminium coil before it enters the fin press for the fin moulding. The process implies a great number of cuts on the fin edge, on the collar and, if the fin is louvered, on thousands of louvers. The cuts eliminate the coating and expose the metal. In reality this is NOT a protection against the corrosion.

Post-coating: it is a procedure in which the coating is applied after the complete assembly of the coil. In this way the coating covers effectively all the finned surface including the fin edges. Until the coat remains in place there is no contact between metal and air. There is no doubt therefore that the post-coating method is the correct answer to corrosion problems.

The AiAX Coatings products and application methods answer the above requirements and bring to customers a superior level solution tested in years of experience.

Post-Coating: a higher cost compared to Pre-Coating

Obviously the post-coating has a higher cost compared to pre-coating for various reasons:a) transport costs, as the treatment is almost always carried out in a factory different from that of the coil manufacturer;

b) packing costs, the coils must be protected for transport;

c) cost of the product which is of superior quality and is applied in higher thickness than that of the pre-coating process.

Different systems of Post-Coating

Having already shown that the only method that makes sense from the point of view of corrosion protection is the post-coating one let us see which are the available methods:1 by immersion

2 by spraying

3 by flooding

This first list of possible solutions must be immediately confronted with a fundamental and not to be ignored element: the anticorrosion protection must be re-applicable.

The experience shows, in fact, that there is no method that can guarantee indefinitely in time against the corrosion. It is always necessary a maintenance which keeps or reinstates the optimal resistance conditions of a just applied treatment.We repeat what already mentioned: any non re-applicable method has a time limited duration and should be considered an unvalid solution. The duration depends from ambient conditions and can , in limit cases, be of only few months.

The immersion method is not re-applicable by definition. There are also limitations in the coil size that can be treated as the immersion baths do not exceed 4-6 metres of length. The two other methods (by spraying and by flooding) are re-applicable and are the only systems which can, according to our experience, be considered safe from the point of view of corrosion protection.

THE ANTICORROSION PROTECTION MUST BE RE-APPLICABLE

The solution is the AiAX Coatings method

A good anticorrosion protection must consider two factors:Penetration: it is necessary that the protection coating is total, i.e. that also the coil internal surface, most difficult to reach, is coated. If a part of the surface is uncovered the corrosion can start in that point and, once started, will expand under the coat layer. Leaving uncovered spots is equivalent to render useless the whole treatment with waste of time and money.

Fin edge coverage: the most delicate point is surely the fin edge where the metal thickness is less than 200 micron and where, due to the limited surface support, it is higher the risk that the coating may not adhere perfectly. Furthermore the fin edge, more exposed to the air flow, can be subject to erosion from solid particles carried by the air.

With 10 years of experience in the flooding process we offer to our customers a guaranteed result and quality

Years of experience have convinced us that the absolute security of penetration of the protection in the inner parts of the fin pack cannot be obtained only through a spraying procedure. In many cases the penetration stops at few centimetres from each side of the coil and the quality of the result depends substantially from the operator skill and attention.

The flooding process, extensively experienced by us, eliminates any doubt and guarantees a complete penetration even of finned packs of more than one metre thickness.

A specific coil support structure, tested for some time before the final set-up and a controlled viscosity product allow not only fast working times but also homogeneous and operator independent results. The controls, periodically carried out on samples, show a constance of protection thickness over the entire internal coil surface.

For further protection of the fin edge, which we have noticed to be the critical point of the coil, a second coating by spraying is superposed to that applied by flooding.

The flooding method and the use of a water based product represent a substantial progress in the state of the art of the anticorrosion protections of coils.

The flooding method and the use of a water based product represent a substantial progress in the state of the art of the anticorrosion protections of coils.