Designer section

Energy efficiency is a focal point in designing new buildings and in retrofitting old ones.The condenser coil of a chiller can lose part of its heat exchange capacity even in less than one year from the date of its installation and the velocity of deterioration depends from the local environment.

A case history: chiller of 329 kW cooling capacity

In order to evaluate the impact on energy costs of a chiller with untreated condenser coils we have analysed the energy consumption in conditions of average air pollution, typical of an urban environment.The data included in this example are the results of studies made by our R&D department in cooperation with some major european manufacturers of high efficiency chillers and rooftop units. We do not pretend to have treated the subject in an exhaustive way but we feel sure that the end results are of interest to the energy conscious engineers.

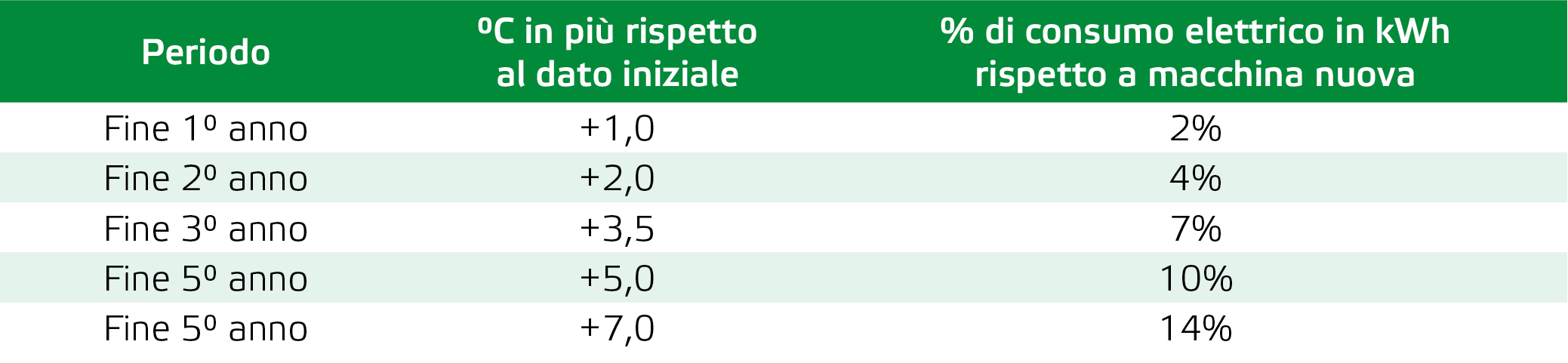

The experience of the last fifteen years of direct observation shows that the condensing temperature of chillers increases in time with respect to initial conditions.

Particularly we noted that, as an average, to every degree °C of increase in the condensing temperature corresponds an increase of electric consumption of about 2% (consumption of the compressors only).

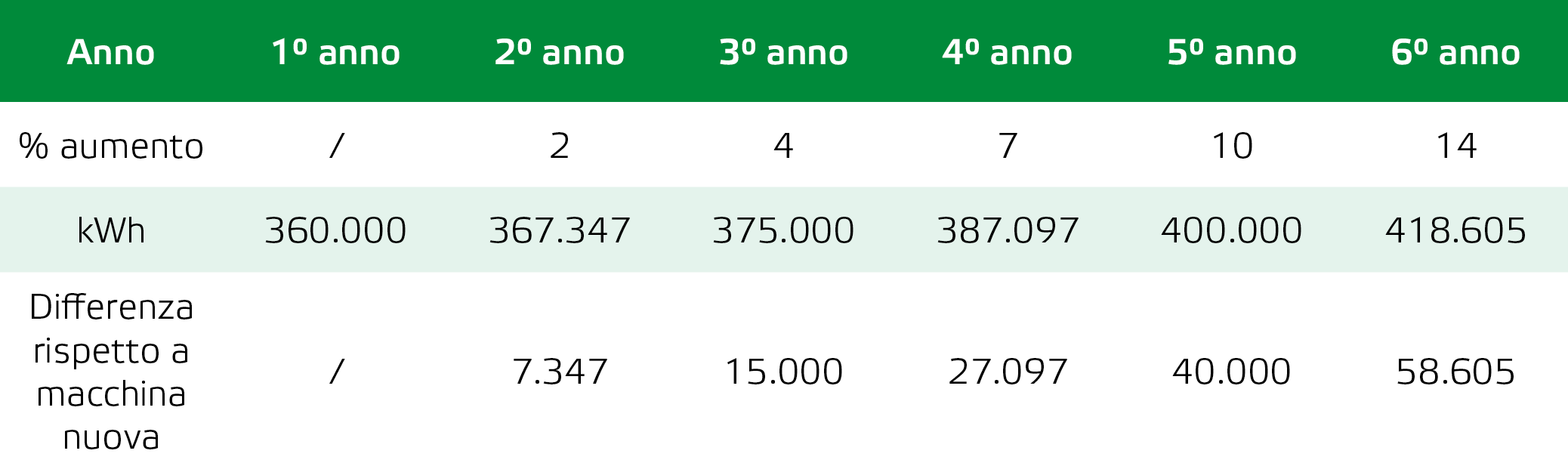

TAB.1

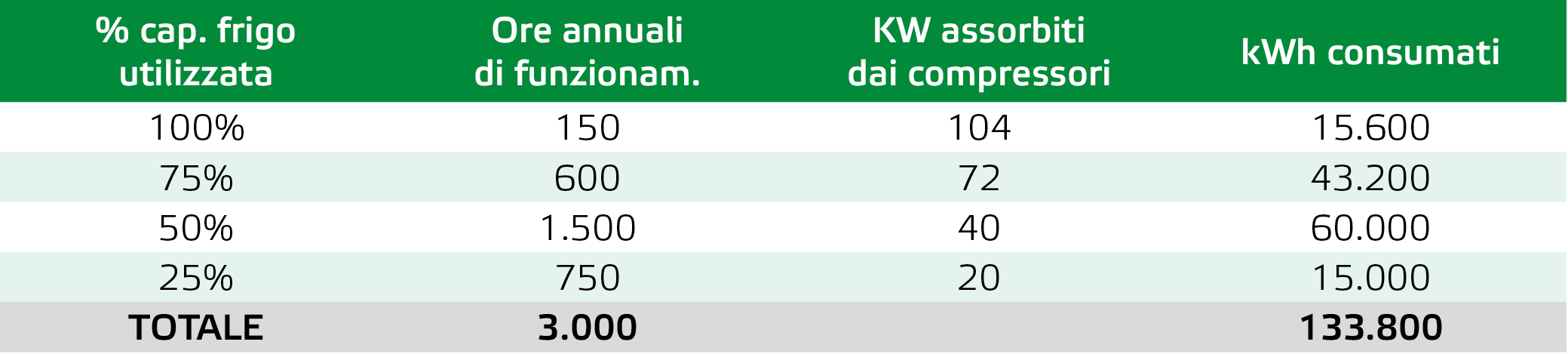

Let us take, as an example, a chiller with four scroll compressors of about 329 kW of cooling capacity (water 12-7°C and ambient air 35°C) with a compressor EER=3.17. The chiller is used in a comfort installation. We shall have about 3000 hours of yearly operation with a bell shaped load profile which, for ease of understanding, we approximate as per the following table.

TAB.2

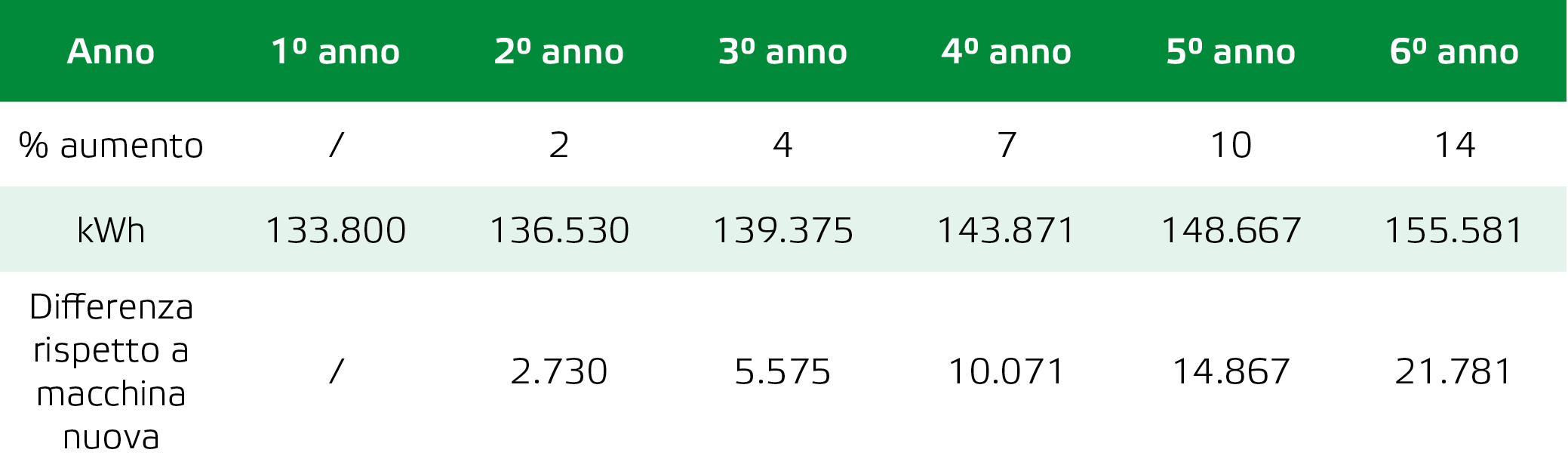

TAB.3

To this cost, conservately calculated, even if by broad outline, it should be added the longer time of chiller operation to reach the desired temperature level.

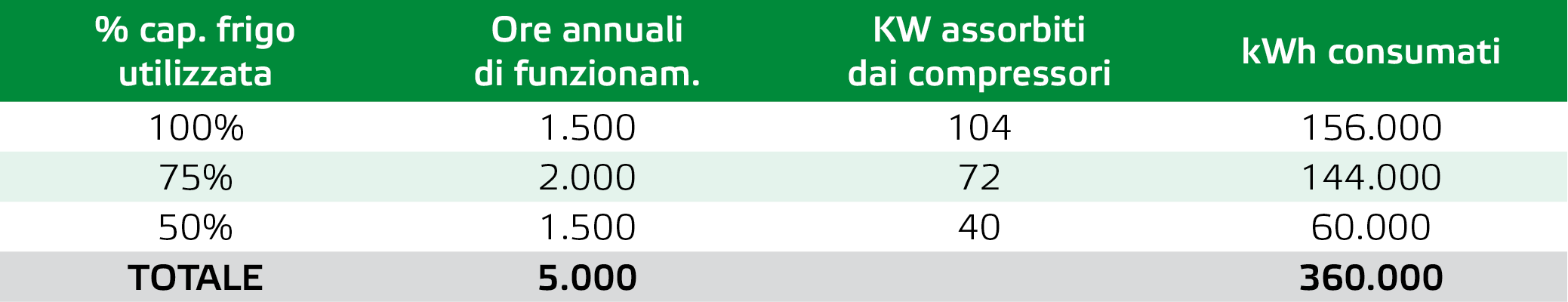

The above example would be even more significant were the chiller operating in an industrial installation in which the yearly hours would be more than 3000 and with a more onerous load profile. Again as an order of magnitude we use the same example in an industrial situation of process water cooling.

TAB.4

Due to the coil deterioration the consumptions will be those of Table 5.

TAB.5

Even class A units, after a certain period of time, depending on ambient conditions of the site of operation, would decrease their performance without a proper anticorrosion treatment in the condenser coil.

As a cost index the application of an AiAX Coatings treatment on the coil of the example chiller would be worth less than one third of the added cost of Table 5.The pay back period would be around 3 years for a comfort installation and less than 2 years for an industrial application.

The application of an AIAX Coatings treatment reduces the risk of refrigerant leaks and of stopping the chiller and ensures an optimal performance for the whole life cycle of the installation provided there is an easy and low cost maintenance (periodical washing with water ad detergent).

Technical Tender Specifications

Hereinafter it is possible to download the technical specifications for tenders.

Aiax Silver Flow - AIAX Silver Spray

Recommended for all thicknesses of the finned pack.

Application is possible both for ”Flooding Method” and spraying procedure.

Tender specification - Silver Line